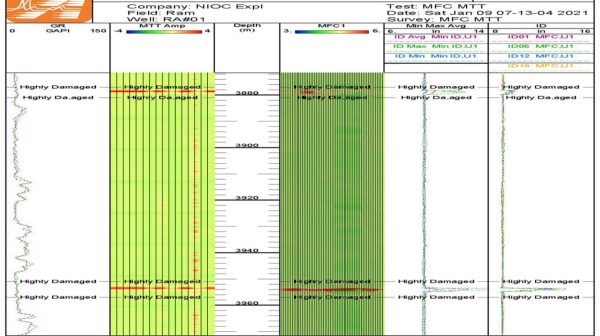

MTT (Magnetic Thickness Tool)

MTT (Magnetic Thickness Tool) is a magnetic inspection tool designed to evaluate the thickness and general condition of steel casing and tubing in oil and gas wells. The tool operates using a magnetic field and is primarily used to detect uniform m metal loss, general corrosion, and major wall-thickness variations in casing strings. MTT is commonly applied as a screening tool to assess overall casing condition and to identify zones that may require further detailed inspection.

Operating Principle

The operation of the MTT tool is based on magnetic field generation. During logging a strong magnetic field is applied to the steel casing Variations in casing thickness alter the magnetic flux density Sensors measure these magnetic field changes. Any reduction in metal thickness or major corrosion alters the magnetic response, allowing evaluation of casing integrity.

Advantages

- Suitable for rapid assessment of overall casing condition

- Effective detection of uniform wall thickness reduction (General Corrosion)

- Simple and stable operational performance

Specification

| Model | DCH70- 200D |

| Temperature rating | 175°C |

| Pressure rating | 103.4MPa (15000 psi) |

| OD | 70mm(2.75in) |

| Length | 2162mm |

| Weight | 30kg |

| Max logging speed | 450m/h |

| Measurement range | 114.3mm~244.5mm |

| Sensor amount | 16 |