EMDS (Electro-Magnetic DefectoScope)

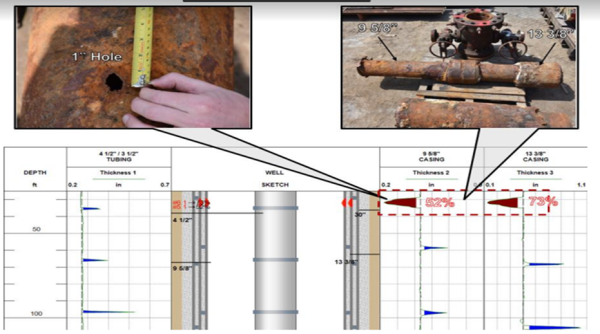

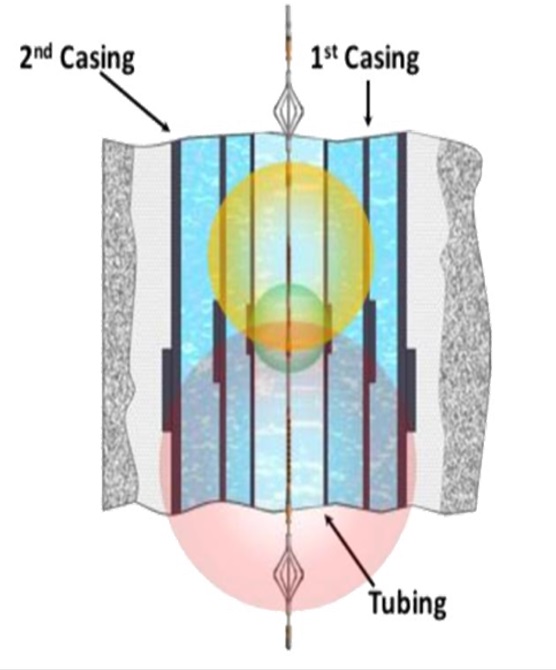

EMDS (Electro-Magnetic DefectoScope) is an advanced electromagnetic inspection tool designed to evaluate casing integrity in oil and gas wells. The tool is developed to detect internal and external corrosion, metal thickness loss, and localized defects in single-string and multi-string casing systems, with the capability to evaluate up to three concentric casing layers.

EMDS operates without requiring direct contact with the casing wall and delivers reliable performance even in the presence of heavy wellbore fluids. It provides accurate monitoring of casing condition and plays a critical role in corrosion management programs and overall well integrity assurance.

EMDS Operating Principle

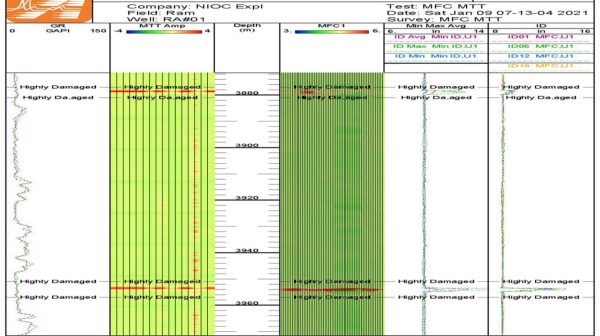

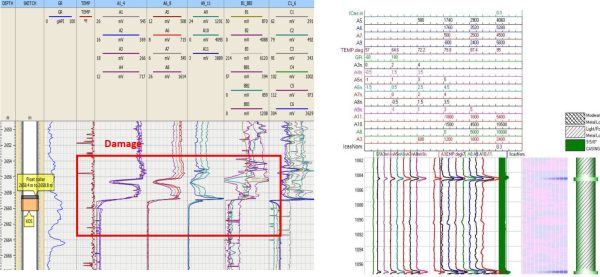

generates high-energy electromagnetic pulses that induce eddy currents within the casing metal. After the pulse transmission, the induced magnetic field in the metal decays exponentially.

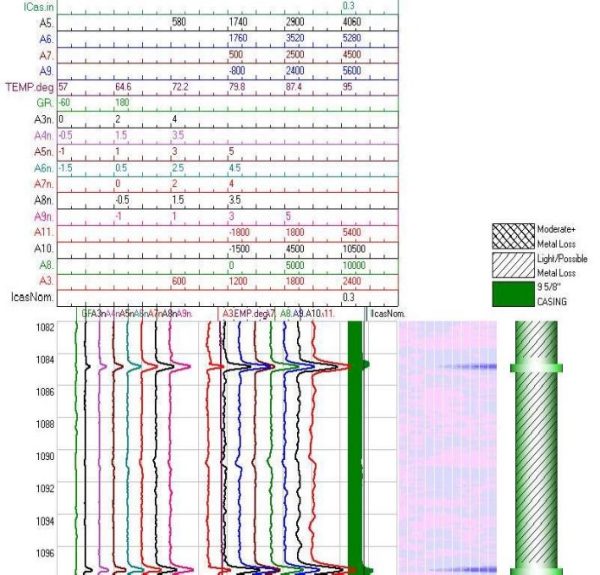

The tool receivers record this field decay at multiple time intervals. The rate of signal decay is directly related to the remaining metal thickness and the presence of defects such as corrosion or pitting, enabling accurate assessment of casing condition.

Advantages

No requirement for direct contact with the casing wall

Capability to simultaneously evaluate up to three concentric casing strings

High accuracy in determining metal loss

Ability to detect both internal and external corrosion

Specification

|

Max working temperature |

177℃ |

|

Max working pressure |

103.4MPa(15000psi) |

|

OD |

43mm(1.69in) |

|

Length |

2300mm |

|

Weight |

10Kg |

|

Max logging speed |

400m/h |

|

Measurement range of pipe diameter |

(62~324)mm(2.44in~12.75 in) |

|

Measurement range of single pipe thickness |

(3~12)mm(0.11in~12.75 in) |

|

Total max thickness of double pipes |

25 mm(0.98in) |

|

Measurement error of single pipe thickness |

0.5mm(0.019in) |

|

Measurement error of casing through tubing |

1.5mm(0.059in) |

|

Min length of longitudinal damage |

50mm(1.96in) 2.5in single pipe 70mm(2.75in)5.5in single pipe 150mm(5.90in.)5.5in casing through tubing |

|

Min length of transversal damage |

1/4 circumference |